Learn the details behind skate technology from expert Fred Ahrens, PE (Turbine Engine Bearings, Seals & Systems Design & Analysis Professional Engineer)

Elements of Machine Design

in Selecting Inline Skating Equipment

Abstract Case studies from popular hobbies, such as inline skating, can be a useful pedagogical tool to help create a linkage between the theory covered in a course and field practice, especially for machine design and fluid mechanics. Topics covered in these courses include rolling element bearings, machining tolerances, material properties and lubrication theory that can be directly applied to the selection of inline skating equipment. This article relates to the application of selected topics covered in machine design and fluid mechanics courses (the latter as part of 32-MET-210 Introduction to Thermoscience; at UC-OCAS). To generalize the topic, a brief overview of inline skating is presented to include a summary history of the sport and style types that influence equipment selection. Discussion then focuses on engaging the student interest by the application of class topics to equipment selection.

Abstract Case studies from popular hobbies, such as inline skating, can be a useful pedagogical tool to help create a linkage between the theory covered in a course and field practice, especially for machine design and fluid mechanics. Topics covered in these courses include rolling element bearings, machining tolerances, material properties and lubrication theory that can be directly applied to the selection of inline skating equipment. This article relates to the application of selected topics covered in machine design and fluid mechanics courses (the latter as part of 32-MET-210 Introduction to Thermoscience; at UC-OCAS). To generalize the topic, a brief overview of inline skating is presented to include a summary history of the sport and style types that influence equipment selection. Discussion then focuses on engaging the student interest by the application of class topics to equipment selection.

Background

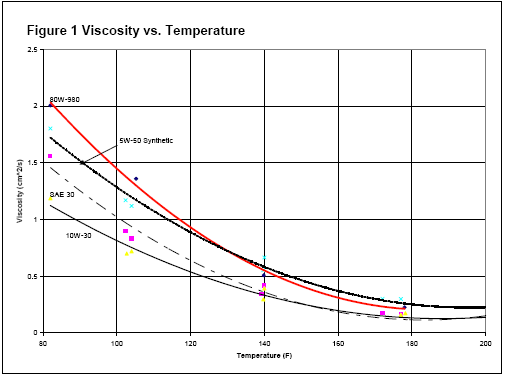

At UC-OCAS, MET students are introduced to basic concepts in thermodynamics and fluid mechanics in the course Introduction to Thermoscience (32-MET-210 taught by the author) with lecture and a supporting lab. The lab concerning fluid viscosity involves utilizing a Saybolt viscometer to flow various oils at controlled temperatures and plotting the viscosity temperature relationship (see fig. 1). This lab tends to draw frequent student comments regarding its length and the apparent abstract nature of the topic. A linkage for this lab can be made by drawing the students' attention to the fact that lubricants marketed for inline skating are very costly on a unit basis (~$7 /oz or more), far more than even premium brand motor oils. The lead-in to this lab relates to a discussion on lubricant viscosity and the impact on product performance. In fact, the marketing sell for lubricants in this market generally focuses on traction torque or its proxy, which is directly influenced by viscosity.

This article will focus on equipment selection in the context of applying mechanical engineering principles to avoid marketing traps and satisfying functional needs while engaging the student interest in the course material. We begin with a brief history of the sport then describe, in summary form, the styles influencing equipment selection and finally discuss the issue of bearings, lubricants and wheel selection. These three machine elements are the primary differentiator between price points and have the largest impact on the products'; performance characteristics.

History

Inline skating can be an enjoyable and highly effective fitness training activity. It has approximately the same calorie burn rate as running with less than half the impact load.

The earliest known conceptualization of an inline skate dates back to the 1700's when a Dutchman attempted to simulate ice skating by nailing wooden spools to strips of wood attached to his shoes. Versions of the in-line skate resurfaced periodically, but the concept did not catch on. Given the technology of the time, in-line skates could not be designed to function as well as conventional roller-skates. By 1930, roller skates had found a permanent place in society. In 1980, two hockey players chanced upon a set of inline skates and found them to be ideal for off-season training. They subsequently formed the Rollerblade Company, re-introducing inline skates to the mainstream [1]. Beginning in the 1990's, inline skating has enjoyed immense, and growing, popularity and has moved to entirely new market segments. While still having a strong hockey following, the sport now has crossovers from skate boarders (aggressive) and, most importantly, has penetrated the fitness market.

Disciplines

There are four broad categories of inline skating: aggressive, hockey, fitness/recreational, and speed skating. While this categorization is not exhaustive and omits crossover styles (like exhibition) it does include the most distinct types. The four identified styles are described as follows:

- Aggressive: This style is characterized by brazen stunts including half pipe (a U-shaped trough that bladers jump on), sliding down railings, jumping stairs and "wall walking". These blades are generally very rugged, have grind plates on the frame (to protect the frame and allow easier sliding on railings) and have small and very hard wheels.

- Hockey: As noted, this is where inline skating evolved. It allows hockey players to train off-season and without recourse to an indoor ice skating rink.

- Recreational/Fitness: This is the largest market segment because it captures the fitness crowd. When one goes to a sporting goods store, the majority of the skates available usually fall into this category. Price points are anywhere from $25 to about $200. Above $200 lies the more specialized equipment (mostly speed skating).

- Speed skating: Speed skating is really a separate category because the equipment is more specialized (and expensive). For example, a speed blade typically has an additional wheel (five wheels instead of four) on each frame, larger wheels and mid cut boots. There will also be a more complex frame geometry in an effort to keep weight down and compensate for the weight penalty of the 5th wheel.

There is a lot of equipment that can be used for the first three categories but when we talk about high-end fitness or speed then the selection becomes more specialized. For example, speed blades would not be suitable for aggressive skating.

Back to top

Machine Elements:

Engineering Reality vs. Marketing

Bearings, lubricants, and wheels are the three primary determinants of product performance. Other factors such as boot ergonomics, stiffness and frame geometry are not to be ignored, however. The mythology in the sport literature is voluminous with little product performance data. For example, what is the traction torque of a really fast bearing? What is the viscosity of that super slick lube? And, why does it cost $7.00 per oz instead of 10 cents per oz for a typical 80W-90 gear oil? Some basic engineering fundamentals will help keep money in your pockets and the wheels on the ground (except for aggressive skating).

Bearings

Inline skates use rolling element radial ball bearings. The standard size is the 608 (common in vacuum cleaner motors) which is 8mm ID, 22mm OD by 7mm wide [2] and are of a steel (typically 52100) construction. There are other sizes available like the 688 mini, but the 608 is the standard. When shopping for these bearings, the marketing "value proposition" usually centers on its ABEC rating. It is said that the higher the ABEC rating the better.

The ABEC, annular bearing engineering committee, standards control the manufacturing tolerance of the bearing. The higher the ABEC rating the tighter the tolerance. For example, a 608 ABEC 1 bearing has an OD tolerance of .0000" to -.0004" while an ABEC 7 is .0000" to -.0002" [3] . Take note, this is not related to IRC, internal radial clearance, it is only the production tolerance band. The relevant question is whether a higher ABEC rating (and higher cost) equate to lower traction torque (what you feel when you blade) and the short answer is no.

For low DN (bore ID, mm x RPM) bearings, less than 100,000 DN, the manufacturing tolerance does not have a significant impact. The ABEC rating becomes more important at high DN (around 1 million) where dynamic considerations (like ball excursion) come into play. For comparison, a blader doing around 12 mph on 80MM OD wheels would be at 10,245 DN. This is essentially a static load case. This is essentially a static load case. Generally, a high ABEC rating is important for bearings used in high DN applications where rolling element dynamics become important or high precision instruments where the bearings would add tolerance stack that degrades instrument precision.

The other choice to make is whether to buy the conventional

steel bearings (the most common) or go to the extra expense of a hybrid ceramic.

The bearing material will affect fatigue life, corrosion susceptibility and temperature capability of the bearing. A typical bearing, for inline skates, will be made from 52100 steel (a high carbon steel) which is quite adequate for low load and low DN applications like blading. A hybrid ceramic has Silicone Nitride (SiN) balls within a steel inner and outer race. Hybrids have far superior characteristics at higher speeds (> 1.5 million DN) than steel bearings. The reason is that SiN is lighter than steel so the centrifugal loads (and hence contact stress) is lower resulting in a longer fatigue life. SiN also has a lower thermal expansion coefficient so the IRC does not change much, reducing the thermal pre-load effect. As an added bonus, SiN is impervious to corrosion and appears to be more damage tolerant. The marketing literature claims that hybrids require less lubrication. The author's test experience with hybrid ceramics (for missile engine applications) does not support this assertion. It is likely that this claim is based on the fact that hybrids can run at higher temperatures (lower thermal expansion) and is simply more forgiving of lubrication deprivation. Additionally, the contact zone between the ball and race is lower thus viscous heat generation is lower then a comparable steel bearing. However, this would not be noticeable to a blader. It is possible that hybrid ceramics may provide a marginal benefit in a skate application in spite of the 50% to 300% cost increase insofar as they are more tolerant to corrosion and lube deprivation.

The primary drivers for traction torque, the most noticeable attribute to a blader, will be the internal geometry like race/ball finish, ball diameter to race curvature, the number of rolling elements, cage/ball clearance and lubrication. The ABEC rating does not directly control the traction torque.

In conclusion, for aggressive and hockey bladers, an ABEC 1 is more than sufficient. Also, the quality level on all the reputable brands is at ABEC 3 or better in any case (even if marked ABEC 1). For a casual fitness blader (20 minutes typical session) an ABEC 3 or 5 will suffice. For the hardcore fitness types (longer than 1 hrs per trip) an ABEC 5 or hybrid would be suitable. It should be noted, anecdotally, that while the ABEC rating, itself, has no relevance to an inline skater there may be quality differences between the low end of the market (ABEC 1 or "precision") and the high end (ABEC 7 and hybrid). A possible hypothesis for this is that there is significant market segmentation in the inline skating equipment market. Those purchasing celebrity-endorsed hardware will be less price sensitive but much more attentive to product characteristics. Thus, while an ABEC 3 bearing will be produced using equipment and processes common to an ABEC 1, there will be more pricing power on the ABEC 3 bearing due to market perception.

Back to top

Lubricant: to grease or not to grease

The purpose of a lubricant in the bearing is to provide a fluid film for elastohydrodynamic lubrication (EHL) lubrication, convey heat out of the bearings and guard against contaminants. For inline skating there are two choices (if not buying pre-packed grease bearings); grease or oil lube. Each has its advantages.

Grease lubing has the following benefits: it is cheap and lasts a long time between maintenance intervals. Greases also provides superior contamination resistance which is good for those who blade in wet or sandy conditions. The downside is that a grease packed bearing has a noticeably higher traction torque.

Oil lubing is best for those who desire the absolute lowest running torque and are willing to tolerate a higher maintenance level for their hobby. The question is what lubricant to select? The lubricants available sold specifically for inline skating applications typically sell for $5-$7/oz compared to less than $.11/oz for a premium motor or gear oil. What is the difference? Typically for a low load, low speed application such as blading, one would want a high viscosity oil with a tackiness additive and perhaps a demulsifier (to get water out of the oil). The high viscosity is mandatory since the EHL film thickness is proportional to the ball entrainment velocity (not very high) and viscosity. Should the film be too thin then adhesive wear, from boundary lubrication, will cause accelerated bearing wear and lower life. Tackiness is important for lube retention in the bearing. Unfortunately, this data is not available for lubes marketed for the inline skate market. It is available for the popular motor and gear oils. So what to do?

The author has been using 80W-90 gear oil since November of 2002. The rationale is that this oil is very cheap (allowing for very frequent servicing that will keep hard particle contamination out) with a high viscosity. During testing (currently 62 trips at 22.8 miles roundtrip), careful attention was paid to signs of discoloration indicating lube deprivation and high running temperature. With one full season using 80W-90 the bearings have exhibited no indications of failure. During the winter months (December through February) the trip time is up to 10 minutes longer on average (from 1hr 35 m to 1 hr 45 min, author's log) when the outdoor ambient temperature is less than 30 F (-1 C). The temperature dependence of oil viscosity is shown in Figure 1 [4] for various motor oils, including 80W-90, and suggests a very strong relationship especially at temperatures below 100 F (38 C), the likely bearing operating temperature range. It should be noted that the temperature environment that the bearing will operate in is not just a function of the ambient temperature but also of the internal heat generation of the bearing.

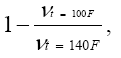

If we take the viscosity temperature coefficient, VTC, as an indication of the variation of viscosity with respect to temperature, where V is viscosity and VTC =

If we take the viscosity temperature coefficient, VTC, as an indication of the variation of viscosity with respect to temperature, where V is viscosity and VTC =  , it can be seen from figure 2 [4] that the viscosity of the 80W-90 oil is more

, it can be seen from figure 2 [4] that the viscosity of the 80W-90 oil is more  sensitive (VTC=. 83) to temperature changes. This would suggest the sluggish winter weather performance is more pronounced than if the SAE 30, 10W-30 or synthetic 5W-50 had been used. The bottom line is that each user will have to evaluate their own blading style and choose according to their needs. Those operating in wet or sandy conditions and desiring low maintenance and high contamination resistance should use grease. Most others should use oil.

sensitive (VTC=. 83) to temperature changes. This would suggest the sluggish winter weather performance is more pronounced than if the SAE 30, 10W-30 or synthetic 5W-50 had been used. The bottom line is that each user will have to evaluate their own blading style and choose according to their needs. Those operating in wet or sandy conditions and desiring low maintenance and high contamination resistance should use grease. Most others should use oil.

The bottom line is that each user will have to evaluate their own blading style and choose according to their needs. Those operating in wet or sandy conditions and desiring low maintenance and high contamination resistance should use grease. Most others should use oil. .

Back to top

Wheel Selection

This is a simpler topic. There are four primary attributes that need consideration; material, durometer, wheel size, and profile.

Durometer refers to the wheel's hardness, a critical attribute. Softer wheels like 78A provide better traction but wear much quicker and have a higher rolling resistance. Harder wheels last longer, have a lower rolling resistance but have slightly less traction. Some inline groups will list "rebound" as a primary factor as well, but this is merely a proxy for durometer. Typically the wheel is polyurethane, otherwise the material will likely be a proprietary composition.

Size refers to the wheel's OD (orbital diameter -- Liz). A speed or fitness blader will want a larger wheel (preferably 80MM) since these offer a lower rolling resistance. This is true because the larger wheels have a smaller contact area for a given load and the resultant reaction vector (drag, vertical weight reaction) will be more vertical. There is the added benefit of enabling the blader to roll through debris easier. It should be noted, however, an inline skate that can accept a large wheel will need a longer frame. This is good for speed and distance, since it is more stable, but makes them sluggish for hockey or aggressive skating.

Profile, the wheel cross section, is equally important. A speed or distance blader will want an ellipsoidal or tapered profile to minimize the contact area and reduce drag. Aggressive bladers typically use a flat profile to maximize contact area and stability. Hockey wheels have a nearly circular section since this style requires more stability than speed skating but entails more sprints than aggressive.

Back to top

Conclusion

This article was not meant to be a definitive guide to inline skating equipment selection but rather a discussion on how one can attempt to apply basic mechanical engineering principles when buying inline skating equipment. With the proper equipment (especially protective gear!) inline skating can be extremely beneficial to personal fitness and weight-loss programs, is fun, and is a cool way to show machine design and fluid mechanics in action!

More importantly, linking the course material to a popular hobby that the students can relate to helps increase student interest and participation in the course.

About the Author

Fred Ahrens, PE is an adjunct instructor at the University of Cincinnati College of Applied Science where he teaches courses in mechanical engineering technology. Mr. Ahrens’ industry experience specializes in the design, analysis and test of bearings, seals and drives.

The author can be reached at: fredming@fuse.net

References

[1] Rollerblade, www.rollerblade.com

[2] INA Group, www.medias.uk.ina.com

[3] ABEC Standard, Anti-Friction Bearing Manufacturers Association

[4] Ahrens, et al, Internal documents

Back to top